How to judge the quality of LED strips? Solutions to common faults of LED strips

How to judge the quality of LED strips?

1. Look at the packaging

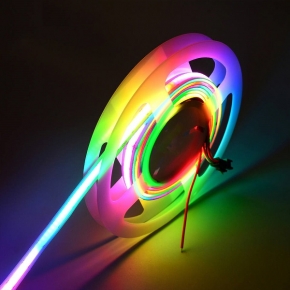

Regular LED light strips will be packaged in anti-static coils, usually 5 meters per roll or 10 meters per roll, and then sealed with anti-static and moisture-proof packaging bags on the outside. The counterfeit version of the LED light belt will use recycled reel for cost saving, and then there is no anti-static and moisture-proof packaging bag. If you look closely at the reel, you can see that there are marks and scratches left by the removal of the label on the outside.

2. Look at the solder joints

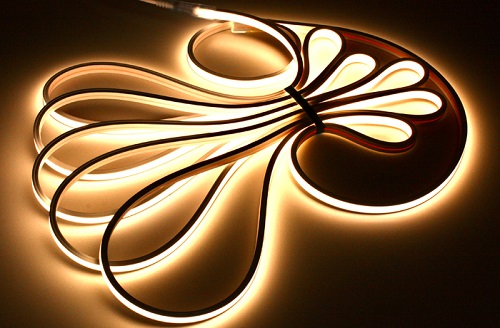

The LED strips produced by regular LED strip manufacturers are produced by SMT patch technology, using solder paste and reflow soldering. Therefore, the solder joints on the LED strip are relatively smooth and the amount of solder is not too much. The solder joints extend from the FPC pad to the LED electrode in a circular arc shape.

3. Look at the cleanliness of the surface of the LED strip

If the LED light strip produced by SMT process is used, the cleanliness of the surface is very good, and no impurities and stains can be seen. However, if the counterfeit LED light strip produced by hand soldering process is used, no matter how it is cleaned, there will be stains and cleaning traces remaining on the surface.

4. Look at the label

The regular LED light belt packaging bag and reel will have printed labels instead of printed labels.

5. Look at the attachment

The regular LED light strips will be enclosed in the packaging box with instructions for use and light strip specifications, and will also be equipped with LED light strip connectors or card holders; while the cottage version of the LED light strip packaging box does not have these accessories, because After all, some manufacturers can still save while saving.

6. Look at the quality of FPC

FPC is divided into two types: copper and rolled copper. The copper foil of the copper-clad board is protruding. If you look closely, it can be seen from the connection between the pad and the FPC. The rolled copper is closely connected with the FPC and can be bent at will without the phenomenon of pad falling off. If the copper-clad board is bent too much, the pad will fall off, and if the temperature is too high during maintenance, the pad will fall off.

Analysis and maintenance of common failures of LED strips

1. Static electricity burns out

Because the LED is an electrostatic sensitive component, if the electrostatic protection work is not done well during the production process, the LED chip will be burned out due to static electricity, which will cause the false death of the LED strip.

Solution: Strengthen electrostatic protection, especially the soldering iron must use anti-static soldering iron. All employees who come into contact with LEDs must wear anti-static gloves and electrostatic rings in accordance with regulations, and tools and instruments must be well grounded.

2. Short circuit

Many LED strips emit poorly because the LED pins are short-circuited. Even if the LED lights are changed, they will short-circuit again when they are energized again, which will burn out the LED chips.

Solution: Find out the real cause of damage in time before repairing, do not rashly replace the LED, repair or directly replace the entire LED strip after finding the cause of the short circuit.

3. High temperature damage

The high temperature resistance of LED is not good. Therefore, if the welding temperature and welding time of the LED are not well controlled during the production and maintenance process, the LED chip will be damaged due to ultra-high temperature or continuous high temperature, which will cause the LED strip to be damaged. Feign death.

Solution: do a good job in the temperature control of reflow soldering and soldering iron, implement a special person responsible, and special file management; the soldering iron uses a temperature-controlled soldering iron to effectively prevent the soldering iron from burning the LED chip at high temperature. It should be noted that the soldering iron cannot stay on the LED pin for 10 seconds. Otherwise it is extremely easy to burn the LED chip.

4. Moisture bursts under high temperature

If the LED package is exposed to the air for a long time, it will absorb moisture. If it is not dehumidified before use, it will cause the moisture in the LED package to expand due to the high temperature and long time period during the reflow soldering process. The LED package bursts, which indirectly causes the LED chip to overheat and damage it.

Solution: The storage environment of the LED should be constant temperature and humidity. Before the next use, the unused LED must be baked in an oven at about 80° for 6 to 8 hours for dehumidification to ensure that the used LEDs will not have any Moisture absorption phenomenon.

We are the professional manufacturer of led light strips, support OEM and ODM customization, and provide you with personalized lighting solutions. Welcome to contact and cooperate with us!